PDF Brochure Prestressed Concrete Piles

MS 1314, BS 8110 and BS 8004

OKA-PILE

Prestressed Concrete Piles |  | OKA-piles are manufactured in accordance to MS 1314, BS 8110 and BS 8004. They are manufactured to high grade *125mm x 125mm and 150mm x 150mm prestressed concrete square piles most suitable for the changing trend in building and civil engineering industries. Having a great demand for quality concrete piles towards light engineering structures, it is most suitable for replacing tropical hardwood timber piles (Bakau piles). It is also more economical as it is proven to achieve higher strength to weight ratio compared to Reinforced concrete piles in material, handling and driving cost. * piles of other sizes can be made upon request. |

| | Prestressing wires before concreting of OKA square piles. | OKA Readymixed Concrete plant is used to produce quality concrete for the production of prestressed square piles. |

APPLICATIONS

- Low and medium rise buildings

- Pedestrian and other short span bridges

- Factories

- Retaining Walls

- Large drains and culverts

- Road and bridge embankments

- Temporary structures

| Fully computerised batching systems are installed and applied in OKA Readymixed Concrete plant to ensure accurate batching and concrete of superior quality. |

| GENERAL SPECIFICATIONS |

OKA piles being used at site.

| 1.

| PRESTRESSING

Longitudinal wires are stressed to between 70% and 80% of its characteristic breaking stress. Average loss of prestress is 18%. | | 2. | CHARACTERISTIC STRENGTH

for concrete is 60 N/mm².

| | 3. | BREAKING STRESS

of prestressing wires is 1770 N/mm². | | 4. | ALLOWABLE AXIAL WORKING LOAD

Normal conditions for actual load are based on soil conditions and should be determined by load test. The normal allowable axial working load recommended represents the structural capacity of the piles. | | 5. | PILE JOINT

Piles comes with end plate jointings and weldings are required to effect the piles jointing.

| | 6. | LIFTING

OKA - piles are provided with 2 lifting hooks incorporated in the pile at 0.2 times of the pile length from each end. This ensures minimum lifting stress. |

| PILE SPECIFICATIONS | Nominal Size *

| (mm)

| 125 X 125 | 150 X150 | Standard Length

| (m) | 6.0 & 3.0

| 6.0 & 3.0 | Weight

| (kg/m)

| 39 | 57 | | Sectional Area | (mm²) | 15625 | 22500 | Concrete Characteristic Strength

| (N/mm²)

| 60 | 60 | Diameter of Perstressing Wires

| (mm) | 4.0 (4 nos) | 5.0 (4 nos) | | Diameter of Links | (mm) | 4.0 | 4.0 | | Prestress After Losses | (N/mm²) | 3.5 | 4.9 | Allowable Axial Working Load

| (Tonnes) | 22

| 32 |

| MATERIALS SPECIFICATIONS | Prestressing Wire | BS 5896 | Pretensioned Logitudinal Steel | Cement | BS 12 | Ordinary Portland Cement | Aggregates | BS 882 | Washed Mining Sand / 20 mm Granite | Admixture | BS 5075 | Super-Plasticizer | Links | BS 4482 | Spiral 4 mm Dia. Hard Drawn Wires | End Plates | BS 4360 | Mild Steel Plates (Grade 43 A) |

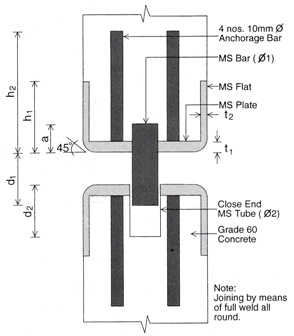

| | JOINT SPECIFICATIONS | | | | 125mm x 125mm | 150mm x 150mm | | a | (mm) | 15 | 15 | | d1 | (mm) | 50 | 50 | | d2 | (mm) | 55 | 55 | ø1 | (mm) | 20 | 20 | ø2 | (mm) | 25 | 25 | | h1 | (mm) | 50 | 50 | | h2 | (mm) | 500 | 500 | | t1 | (mm) | 6 | 6 | | t2 | (mm) | 2 | 2 |

| PILE CAPACITY | Allowable pile working load : W = (0.25 fcu - fp ) Ac where, | | fcu | = | Concrete characteristic strength | | fp | = | Prestress after losses | Ac | = | X-Sectional area of pile |

Go to Top Download PDF Brochure

|