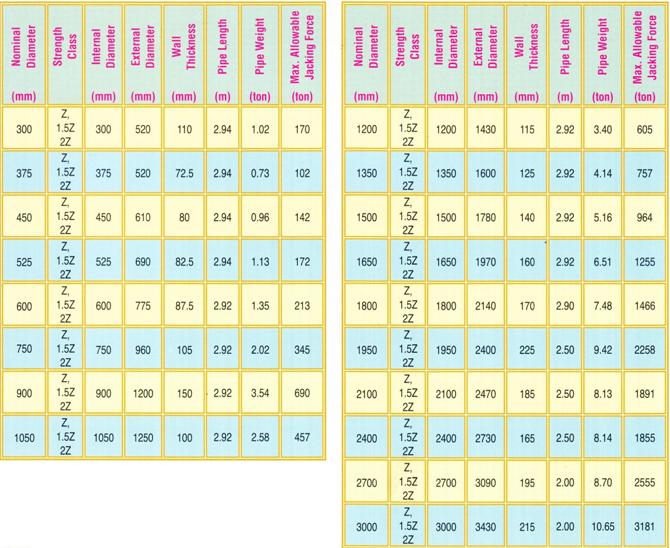

| Range : Diameter 300 - 4800 mm

Applications : Sewerage, drainage, culverts, ducts, tunneling, water pipes

Strength Class : Z,1.5Z,2Z; H,1.5H,2H; 120,180,240 etc.

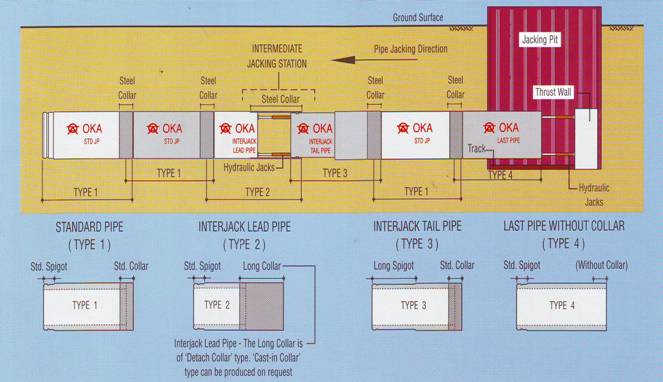

Specially designed and manufactured pipes to suit individual requirements : Extra strength classes (Z/H Plus), internal high alumia cement mortar lining, internal PVC / HDPE lining, sacrificial lining, concrete with PFA, surface protective coatings and other special requirements. | | OKA offers a comprehensive range of precast reinforced concrete jacking pipes suitable for installation with modern generation of jacking techniques and systems.

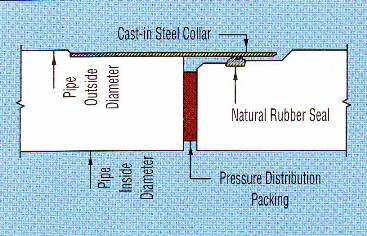

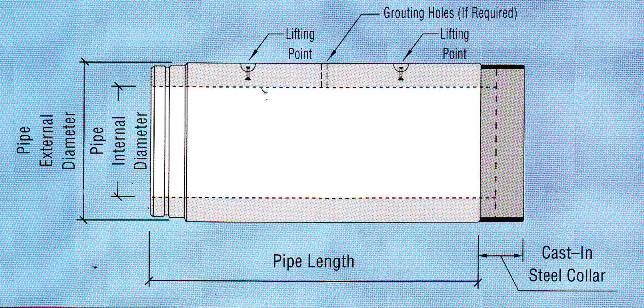

Standard pipes are manufactured with well proven butt end joint with cast-in steel collar and flexible natural rubber seal.

Pipes are manufactured either using spinning or vertical wet-cast process under controlled factory environment with stringent ISO 9001:2015 quality management system. Jacking Pipes are manufactured in accordance to British Standard BS5911:Part 1 or equivalent.

|