|

|

|

Products > Precast Concrete Pipe

|

|

| |

OKA as one of the leading manufacturer of precast concrete pipes, provide an extensive range of spinning spun pipes from nominal diameter 300mm to 1800mm.

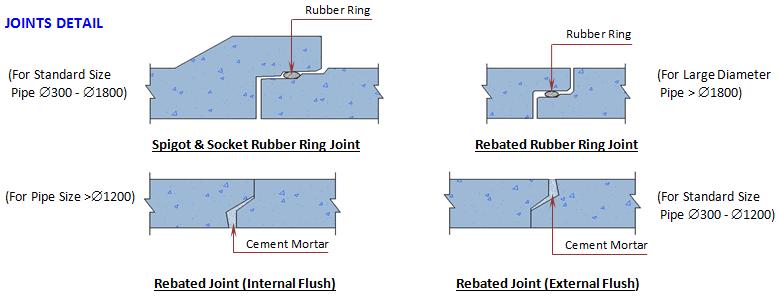

| OKA precast concrete pipes are available with rebated/ogee joint and spigot & socket with rubber ring joint. All pipes are manufactured in accordance to Malaysia Standard MS881 : Part 1 & Part 3 : 1991 under controlled factory environment with stringent ISO 9001:2015 quality management system.

|  |  | | Rebate/Ogee Joint Pipes | Spigot & Socket With Rubber Ring Joint Pipes |

APPLICATIONS

- Drainage & Stormwater Culvert

- Sewerage Culvert

| ADVANTAGES- Fast Installation

Pipe with rebated/ogee joint can be easily installed without sophisticated jacking equipment. This kind of rigid joint method is conveniently installed in properly layered hard and flat ground condition.

- Flexibility

Pipes with spigot & socket with rubber ring joint can offer flexibility in certain degree of turning radius while maintaining the robustness of the pipe. A certain level of deflection due to soil settlement can be accomodated by this kind of flexible joint method.

- Durability

Pipes with protective layer such as high alumina cement (HAC) lining or sacrificial concrete lining provide resistance to continuous exposure to hydrogen sulphide and wide variety of chemical corrosion attacks.

- Quality Assurance

Precast pipes are manufactured under controlled factory environment with stringent ISO 9001:2015 quality management system.

- Superior Strength

Pipes manufactured with centrifugally spun process can achieve an equivalent high compaction due to coupling effect of vibration and centrifugal force.

|

OKA is approved Supplier for sewerage products for SURUHANJAYA PERKIDMATAN AIR NEGARA / SPAN ( previously JPP ).

List of approved products : PRECAST REINFORCED CONCRETE PIPES WITH OGEE JOINTS &

CONCRETE PIPES WITH FLEXIBLE JOINTS FOR DRAINAGE AND SEWERAGE AND PRECAST CONCRETE MANHOLES (HEAVY DUTY)

|

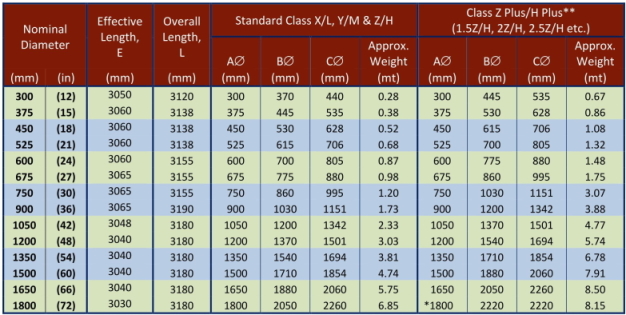

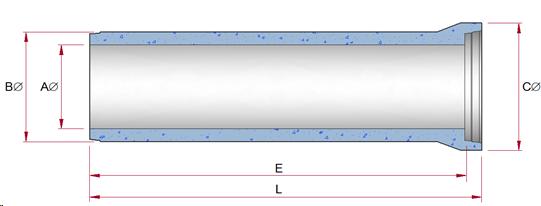

OKA SPIGOT & SOCKET WITH RUBBER RING JOINT PIPES (Comforms To MS 881:Part 1:1991) |

|

| Notes: AΦ : Barrel Internal Diameter BΦ : Barrel External Diameter CΦ : Socket External Diameter |

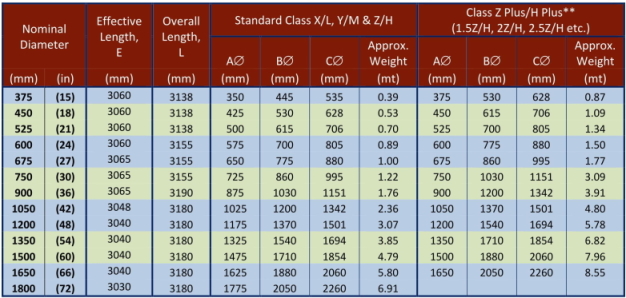

OKA SPIGOT & SOCKET WITH RUBBER RING JOINT PIPES c/w 12mm HAC LINING(Comforms To MS 881:Part 1:1991)

|

|

|

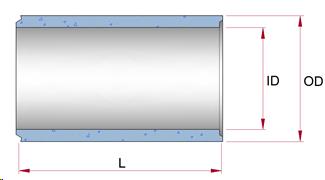

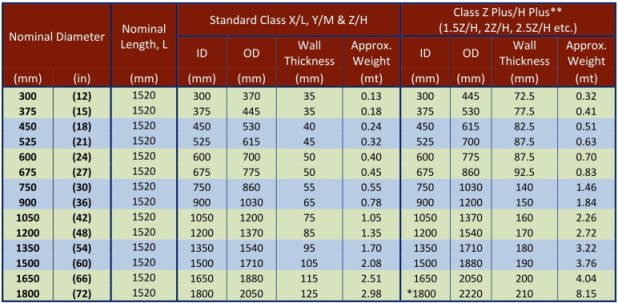

OKA REBATED/OGEE JOINT PIPES (Comforms To MS 881:Part 3:1991)

|  |

Notes :

Class X, Y, Z and Z Plus conforms to AS/NZS 4058:2007

Class L, M, H and H Plus conforms to MS 881:1991

* For Pipe nominal diameter 1800mm (Class Z/H Plus), the nominal length shall be 2500mm.

** Class Z Plus / H Plus denotes 1.5Z/1.5H, 2Z/2H, 2.5Z/2.5H & etc available for selection.

Pipe can be manufactured using PFA cement (Mascrete).

Pipe with sacrificial concrete lining, epoxy coating, PVC Lining or HDPE lining can be manufactured upon request.

Pipes with higher or specified strength can also be manufactured by OKA (Non standard products). |  |

SPECIFICATION - All concrete pipes are to install with correct load line facing either top or bottom point of the pipe circumference. The load line can be identified by marking on the internal barrel surface of the pipe.

- Mimimum cover to concrete pipe culvert is recommended to be 600mm to avoid undesirable point load action. Where the minimum cover cannot be achieved, the concrete pipe shall be surrounded in concrete.

- It is of vital importance for the contractor/installer to have thorough understanding of the specifications/requirements on designed method installation, desinged bedding factor, materials and workmanship in order to ensure satisfactory performance of any installed pipe culverts.

|

PIPE CLASS SELECTION

The suitable pipe class shall be selected and the site construction/installation technique shall be adhered to the authority/consultant’s design criteria and requirements. Pipe class selection is subjected to the following factors : - Pipe installation conditions either in trench or under embankment.

- Depth of fill above the pipe culvert and type of fill materials.

- Type of bedding as constructed at project site.

- Superimposed load conditions

|  |  | Go To Top | | | | Download PDF Brochure |

|

|

|

|

|

| |

|

|