PDF Brochure

PRECAST CONCRETE PILES

Confirm to MS 1314 : 2004

|  | RC Piles at OKA Factory | OKA Readymix concrete Plant |

OKA REINFORCED CONCRETE SQUARE PILES | Design and Code of Practices | The design and manufacture of OKA Reinforced concrete piles is in accordance with : | MS 1314:2004 | "Malaysian Standard for Precast Concrete Piles" | BS 8004:1986 | "British Standard Code for Practise for Foundation" | BS 8110:Pt 1:1985 | "British Standard on Structural Use of Concrete - Code of Practise for Design and Construction". |

| Materials Specifications | Concrete | Characteristic cube strength shall be 45 N/mm2; Water/Cement Ratio < 0.45 | Cement | Ordinary Portland Cement to MS 522 | Aggregates | MS 29 | Reinforcement | MS 144 and MS 146 |

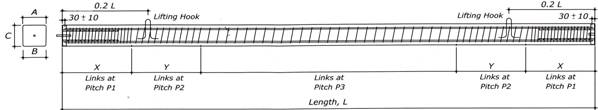

| Design Criteria | The piles are designed and manufactured to withstand loads or stresses due to lifting, stacking, transport, handling, pitching and driving at site. MAIN LONGITUDINAL REINFORCEMENT is designed for lifting, handling and pitching. It is also been taken into consideration for contributing to the axial load capacity :

LATERAL REINFORCEMENT in the form of links is provided to prevent shattering or splitting of pile during driving :

| | All Piles | Minimum 0.6% steel content by volume (at pile head/toe) | | Minimum 0.2% steel content by volume (at pile body) |

| Handling & Pitching | OKA piles are designed to resist bending moment due to single point or two points lifting/pitching. |

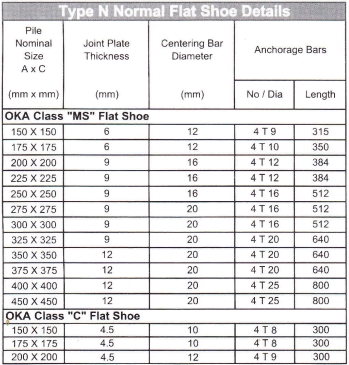

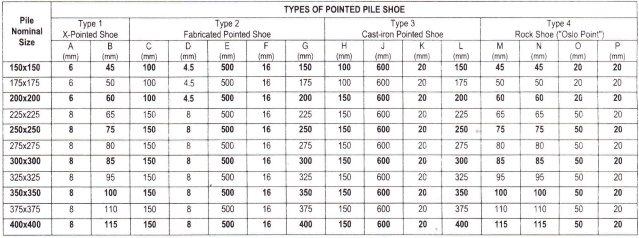

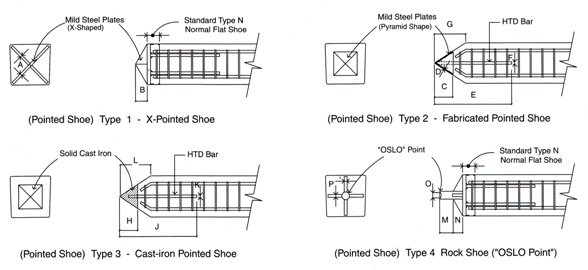

| Pile Shoes | OKA piles come with FIVE alternative type of pile shoes. The type of pile shoe selected depend on driving and soil conditions.

(FLAT SHOE) | | Type N | Normal Flat Shoe

(Flat-ended MS Plate) | ..... | easy to medium hard driving | | (POINTED SHOES) | | Type 1 | X-Pointed Shoe | ..... | moderate to hard driving | | Type 2 | Fabricated Pointed Shoe | ..... | normal hard driving | | Type 3 | Cast-iron Pointed Shoe | ..... | normal hard driving, to penetrate cemented soil layer, pile seating on weak rock | | Type 4 | Rock Shoe

("Oslo Point") | ..... | hard driving and piles seating on hard rock strata |

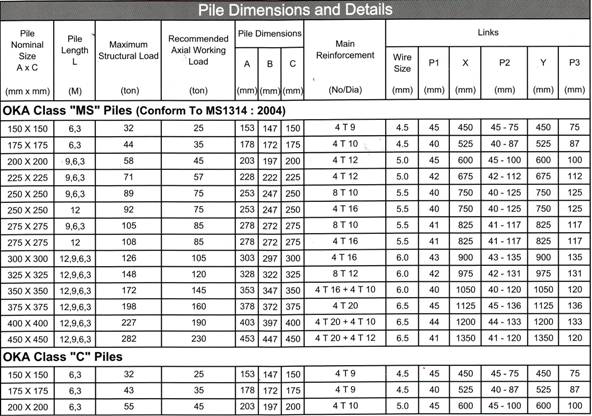

CAPACITY OF PILE

| The maximum allowable structural working load (Safe Working Load) of the pile is calculated in accordance with BS 8004. | | Max. Structural Working Load | = fcu x Ac + fsc x Asc

3.65 | | fcu | Characteristic cube strength of concrete at 28 days = 45 N/mm2 | | Ac | Area of concrete | | fsc | 175 N/mm2 for High Yield Reinforcement | | Asc | Area of steel |

| Notes : | | 1. | OKA Sales "MS" piles are designed and manufactured in accordance with MS 1314 : 2004. | | 2. | OKA Class "C" piles are designed and manufactured in accordance with BS 8004. | | 3. | Concrete used shall be grade 45 with characteristic cube strength of 45 N/mm2 at 28 days. | | 4. | The above structural loads are for reference only.

Actual structural loads are also dependent on other factors especially ground conditions. |

TYPES OF POINTED PILE SHOE

Quality Control

| Quality Control of all materials and components in pile manufacturing is an essential part of the OKA Piling system. To achieve this, regular testing is carried out and maintenaned in accordance with OKA's specifications, relevant British Standard Codes of Practices and Malaysian standard. Results are recorded graphically to ensure trands can be recognised early and for ease of reference each pile carries an identification number. Among the many test carried out are : - Test on concrete cubes for compressive strength.

- Checks on finished piles for straightness, cross-section, alignment of joint and fittings.

- Slump test on concrete batches.

- Test on aggregate samples for grading and silt content.

- Stringent checks on reinforcement cages for steel quality, spacing and stirrups pitch.

|

Go to Top

Download PDF Brochure

|